East Coast Hydraulics’ Cylinder Shop is a full design, fabrication, repair, and rebuild hydraulic cylinder center. All of your needs for any sized hydraulic cylinder can be met here.

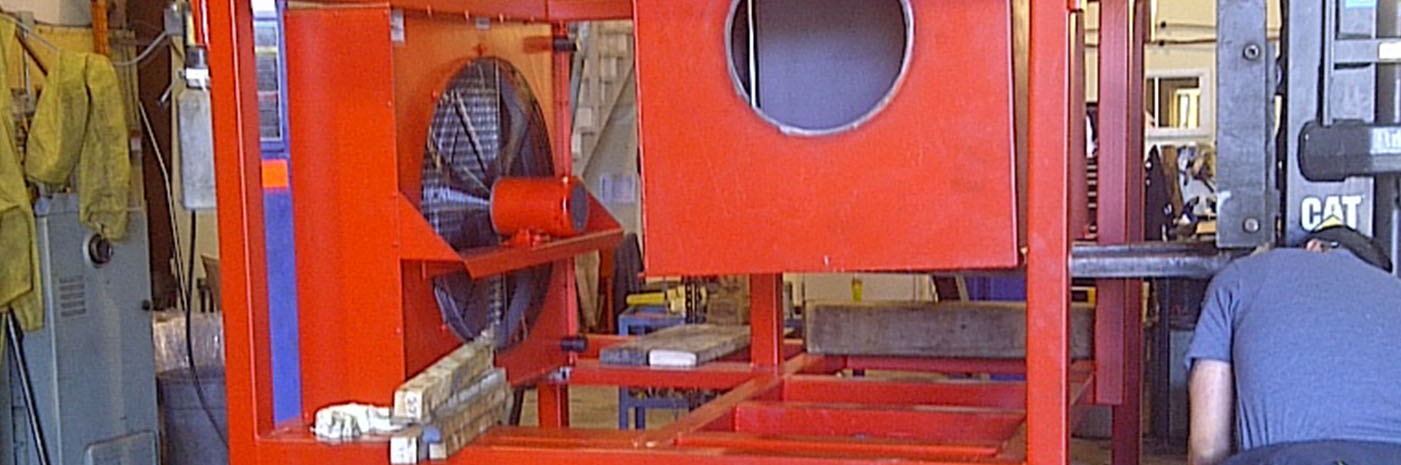

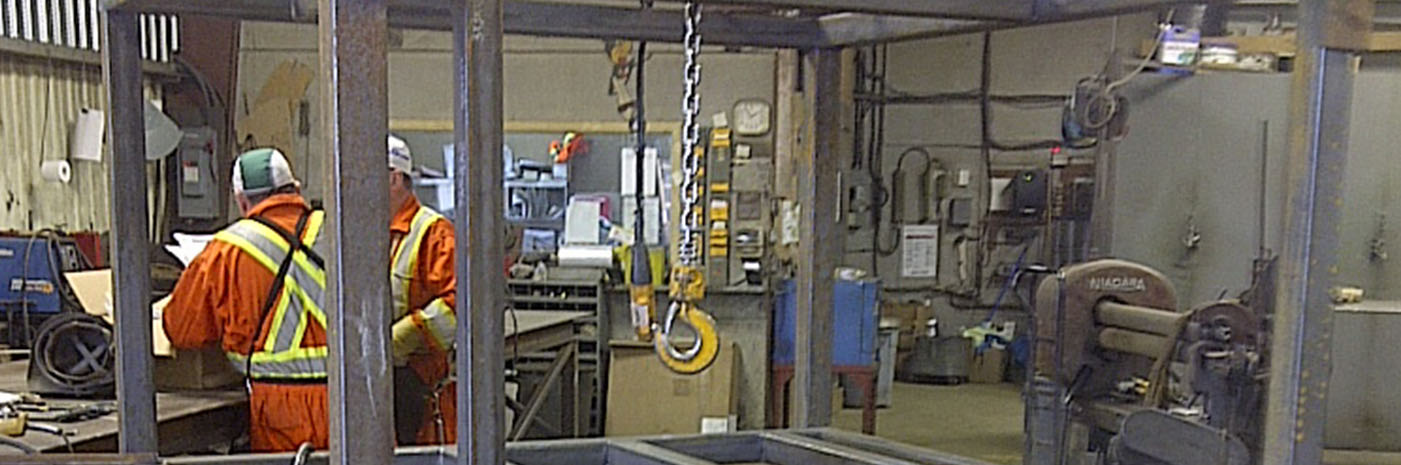

Our shop layout of 4500 square feet is fully equipped to properly handle, inspect, complete work scopes, and return to customer in the utmost professional manner.

From lifting off your cylinder with one of our 2 5-ton overhead cranes.

Our Tuxco ™ cylinder disassembly bench with a length capacity of 20 feet closed and 40' open. This unit is complete with a hydraulic planetary gear head that can provide up to 40,000 ft/lbs of torque to assist in removing shaft nuts and threaded cylinder glands.

We are complete with 4 lathes with a capability to swing 36" diameter material with a 20' length. Our lathes have a digital read out system for accuracy.

Our Milling machine for intricate fabrication and repairing cylinder eyes.

We stock a wide variety of induction chrome shafting in sizes from ½" up to 5" and in metric from 12mm up to 140mm. This would be the standard sizes on all of the Komatsu™, Caterpillar™, and John Deere™ equipment, as well as other recognized brands.

We have 2 machinist on staff who have a combined 35 plus years-experience working on cylinders.

Malleable Steel in stock up to 12" in diameter for fabricating pistons and glands if required.

All Cylinders are tested for bypass with hydraulic oil to a safe working pressure predetermined by our customer written instructions (as per our Quality Assurance Program) and with discussion with our Certified Hydraulic Technicians.

We offer an elaborate Cylinder Management Program for our customers that can be designed to help with your internal predictive and maintenance programs as well as any inventory or tracking system programs you may have in place.

All cylinders that enter our shop are stamped with our work orders and pictures and reports are kept on file for future reference.