Technical Services

End-to-End Hydraulic Systems Engineering & Fabrication

We provide specialized engineering support at the earliest stages of your project to ensure all system requirements are captured and delivered with precision. Our Design & Fabrication services cover the complete lifecycle—from concept development to final system deployment.

Engineering & Design Services:

- Requirements gathering and system definition

- Modeling

- Component selection, materials engineering, and integration planning

- Detailed fabrication drawings and documentation packages

Fabrication & Assembly:

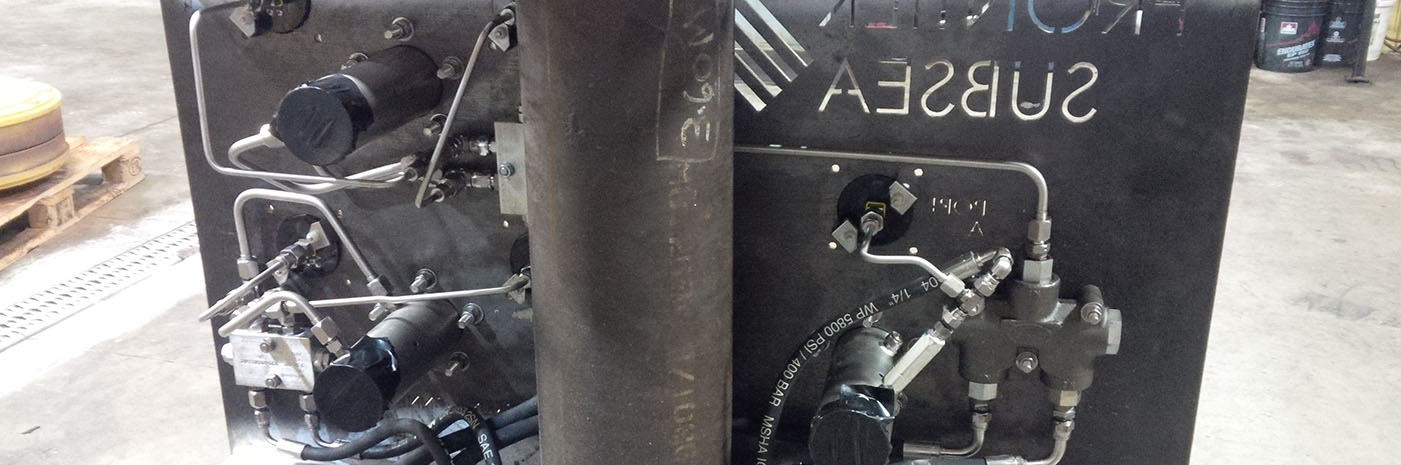

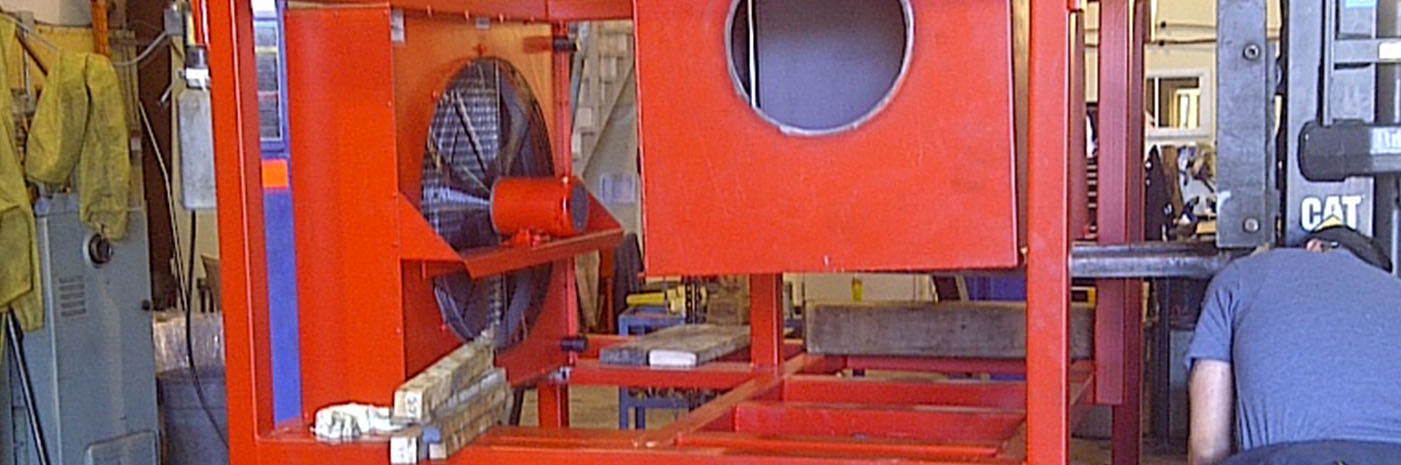

- In-house manufacturing and assembly of custom hydraulic systems

- Integration of hydraulic power units (HPUs), manifolds, piping, and control systems

- Compliance with ISO, API, SAE, and customer-specific standards

Verification & Validation Testing:

- Hydrostatic Pressure Testing

- Hot Oil Flushing to ISO 4406 cleanliness standards

- Factory Acceptance Testing (FAT) to customer-defined protocols

- Leak Testing, Functional Testing, and Load Simulation

- Custom and Industry-Standard Certification (e.g., ASME, CE, DNV, ABS)

Surface Protection & Finishing:

- Custom coating systems for corrosion resistance and harsh environments

- Industrial painting, powder coating, or specialty finishes to spec

- Documentation of surface treatment processes for QA traceability

All systems are subjected to rigorous QA/QC protocols to ensure compliance with engineering requirements and regulatory standards. Optional service packages—such as on-site commissioning, documentation support, and long-term maintenance agreements—are available upon request.